Product

- ALL

- Insulation Gasket Kit

- MECHANICAL SEAL

- PTFE SERIES

- Expanded PTFE

- Modified PTFE

- Filled PTFE

- CNC PTFE Parts

- COMPRESSED FIBRE SHEET

- GRAPHITE GASKET SHEET

- GLAND PACKING & TOOLS

- PTFE Series Packing

- Aramid/Kevlar Series Packing

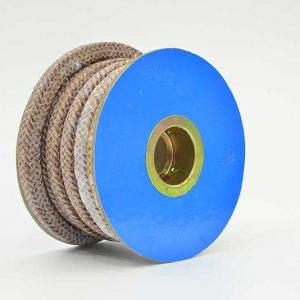

- Synthetic Fiber Series Packing

- Carbon Fiber Series Packing

- Graphite Series Packing

- Plant Fiber Series Packing

- JOINT GASKET

- Spiral Wound Gaskets

- Cammprofile Gasket

- Jacketed Gaskets

- Ring Joint Gasket

- PTFE Bonded EPDM Gasket

- PTFE Envelope Gasket

- Disc Spring

Showing 25–36 of 51 results

-

Read more

The die-formed graphite rings is manufactured from high purity graphite. This ring combine carbon fiber packing ring for gland sealing, such as soot blower, suitable for extreme temperature, it is reduced stem friction, not only protecting axle obviously but also support enough power output of equipment.

- Profile: Square section; V-shaped; wedge-shaped section.

- Application: Mixer, Blowers, valve etc.

- Size: D:6mm to 900mm OD:12mm to 1100mm

-

Read more

Spiral Wound Gasket Dimensions per

DIN Standard

EN1514-2

ASME B16.20(API601) for ASME B16.5 Flanges

For ASME B16.47 Series A MSS SP 44 fLANGE

ASME B16.20 (API601)for ASME B16.47 Series B (API605)

-

Read more

Cammprofile gaskets, well known by grooved gasket, consist of concentric grooves metal core with graphite/PTFE soft layer bonding to both grooved faces. Cammprofile gasket is an effective solution for extreme operating conditions. Metal core ensures the gasket’s stability, and Graphite/PTFE layers protect flange surface undamaged.

Gasket dimensions:

for ASME B16.5 flanges

EN 1092-1 flanges(DIN EN 1514-6) -

Read more

Jacketed gaskets are produced in a wide variety of different materials (in various combinations), in many cross-sections and in many styles. They are suitable for flanges in heat exchangers, pipe flanges, boilers and process equipment.

• Metallic outer shell with asbestos free filler

• The filler material gives the gasket resilience

• The metal jacket protects the filler and resists pressures, temperatures and corrosion -

Read more

Features:

Ring type joints are manufactured according to ASME B16.20 (2007)standards and to API specifcation 6A and17B. Careful control of all manufacturing processes ensures correct surface hardness to give a good seal without damaging flange connections.

Advantages

• Secure sealing action through metal-tometal contact for reliable sealing in high pressure applications

• They are used in the oil field on drilling and completion equipment and in downstream refinery applications. Ring type joints are also commonly used on extremely high-pressure valves and pipework assemblies, along with some high integrity pressure vessel joints. -

Read more

Disc spring, well know by Belleville Washers.

Manufactured to DIN 2093 standard and non-standard.

Material: 50CrV4/60Si2Mn/X 10 CrNi 18-8/X 7 CrNiAl 17 7/X 5 CrNiMo 17 12 2/X 22 CrMoV 12 1/X 39 CrMo 17-1/CuSn 8/CuBe 2/NIMONIC 90/INCONEL X 750/INCONEL 718/INCONEL625 Etc.

-

Read more

JPI Standard Steel Flange for Class 150,Gasket TOMBO JPI

PTFE Bonded EPDM Gasket is made of high-grade EPDM or NBR as the main body, and the sealing part is compounded with a pure PTFE shell that has been specially activated. It has the advantage of adopting a special bonding process to make the PTFE plastic and synthetic rubber tightly bonded, and the overall composite is excellent.

-

Read more

Material: PTFE , Non-asbestos, EPDM, Metal

PTFE Envelope gaskets have three structure PMF, PMS, PFT and PFF. Gaskets are manufactured by gasket core with a PTFE lamination. They combine the mechanical strength, resilience and bolt load retention of gasket with the chemical resistance of PTFE. They are used in equipment with glass; ceramic or glass coated steel flanges. Maximum service temperature is 500oF (260oC), the limit for PTFE.

-

Read more

Application: Chemical, paper, dye and fertilizer industries. Steam, fuels, water, dilute acids and alkalies, organic compounds, oils, greases and solvents, etc.

- Composition:Kevlar Fiber, PTFE/Black PTFE(Graphite impregnant)

- GH1340: White PTFE with Aramid Corner Pacing

- GH1359: Black PTFE with Aramid Corner Pacing

- Temperature (ºC) : -23—260

- Size:3×3mm–50×50mm

-

Read more

Kevlar gland Packing is usually applied to pulp factory, sand slurry tin mine and feed water pump of power plant etc. Braided from high quality Dupont spun Nomex yarns with PTFE-Impregnation and lubricant additive. High cross-sectional density and structural strength, good sliding characteristic, gentle on shaft surfaces. Compared to Kevlar, it do not hurt shaft, also ideal for food industries.

- Composition: Nomex Fiber, PTFE

- Temperature (ºC) -100 – 250

- Pressure (Bar) 100

- Velocity (m/s) 20

- PH 1-13

- Size: 3×3mm–50×50mm

-

Read more

Phenolic Fiber, well know by Kynol Fiber, this material has excellent performance pump sealing. Suitable for abrasive media, and where contamination is not permitted. It has multiple uses in chemical plants and pulp and paper mills, and is regularly used in rotating and reciprocating pumps, washer journals, liquor pumps, refiners and digesters. Applications where graphite impregnation may not be acceptable.

- Composition: Phenolic Fiber, PTFE lubricant

- Temperature (ºC) -200—260

- Pressure (Bar) 200

- Velocity (m/s) 20

- PH 1-13

- Size: 3×3mm–50×50mm