GLAND PACKING & TOOLS

- ALL

- Insulation Gasket Kit

- MECHANICAL SEAL

- PTFE SERIES

- Expanded PTFE

- Modified PTFE

- Filled PTFE

- CNC PTFE Parts

- COMPRESSED FIBRE SHEET

- GRAPHITE GASKET SHEET

- GLAND PACKING & TOOLS

- PTFE Series Packing

- Aramid/Kevlar Series Packing

- Synthetic Fiber Series Packing

- Carbon Fiber Series Packing

- Graphite Series Packing

- Plant Fiber Series Packing

- JOINT GASKET

- Spiral Wound Gaskets

- Cammprofile Gasket

- Jacketed Gaskets

- Ring Joint Gasket

- PTFE Bonded EPDM Gasket

- PTFE Envelope Gasket

- Disc Spring

Showing 1–12 of 22 results

-

Read more

Eliminates problems caused by leaks, seal water, worn shafts and old machines.

This exceptional material saves energy as it lubricates and cools in pressures up to 20 bar.

Plastic tubs 5 kgs. -

Read more

New Type INJ-PAC TOOL is designed by advanced structure. It is more convenient operating and reliable quality.

-

Read more

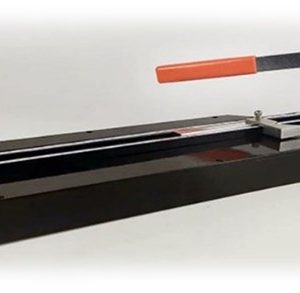

Guillotine Packing Cutter

PACC is the updating design style tools, using the guillotine, but not the knife to cut.

It improves cutting accuracy and efficiency.Its ruler can precisely cut the required length, and the 45° incision perfectly meets the installation requirements of the compression packing.

-

Read more

The removable tips of our flexible shaft extractors deliver multipurpose capabilities for time and cost savings. Our corkscrew bit provides easy extraction for fibrous packings. When removing hardened packing, the woodscrew bit is a suitable option.

-

Read more

Application: Chemical, paper, dye and fertilizer industries. Steam, fuels, water, dilute acids and alkalies, organic compounds, oils, greases and solvents, etc.

- Composition:Kevlar Fiber, PTFE/Black PTFE(Graphite impregnant)

- GH1340: White PTFE with Aramid Corner Pacing

- GH1359: Black PTFE with Aramid Corner Pacing

- Temperature (ºC) : -23—260

- Size:3×3mm–50×50mm

-

Read more

Kevlar gland Packing is usually applied to pulp factory, sand slurry tin mine and feed water pump of power plant etc. Braided from high quality Dupont spun Nomex yarns with PTFE-Impregnation and lubricant additive. High cross-sectional density and structural strength, good sliding characteristic, gentle on shaft surfaces. Compared to Kevlar, it do not hurt shaft, also ideal for food industries.

- Composition: Nomex Fiber, PTFE

- Temperature (ºC) -100 – 250

- Pressure (Bar) 100

- Velocity (m/s) 20

- PH 1-13

- Size: 3×3mm–50×50mm

-

Read more

Phenolic Fiber, well know by Kynol Fiber, this material has excellent performance pump sealing. Suitable for abrasive media, and where contamination is not permitted. It has multiple uses in chemical plants and pulp and paper mills, and is regularly used in rotating and reciprocating pumps, washer journals, liquor pumps, refiners and digesters. Applications where graphite impregnation may not be acceptable.

- Composition: Phenolic Fiber, PTFE lubricant

- Temperature (ºC) -200—260

- Pressure (Bar) 200

- Velocity (m/s) 20

- PH 1-13

- Size: 3×3mm–50×50mm

-

Read more

Chemical, engineering, foodstuff, pharmaceutic industry where contamination is not allowed. Water, steam, oils, fuels, solvents, acids and alkalies except for strong oxidants.

- Pure PTFE yarn braided

- Temperature (ºC) -100 – 260

- Pressure (Bar) 100

- Velocity (m/s) 10

- PH0-14

- Size: 3×3mm–50×50mm

-

Read more

Chemical engineering, foodstuff, pharmaceutic industry where high purity and corrosion resistance is required. Water, steam, oils, fuels, solvents, acids and alkalies except for strong oxidants.

- Pure PTFE yarn, PTFE, lubricating oil braided

- Temperature (ºC) -100 – 260

- Pressure (Bar) 100

- Velocity (m/s) 10

- PH0-14

- Size: 3×3mm–50×50mm

-

Read more

It is most useful in slower shaft speed applications. The rubber core provides a low friction finish and prevents leakage through the braid. Chemical, paper, dye and fertilizer industries. Steam, fuels, water, dilute acids and alkalies, organic compounds, oils, greases and solvents, etc.

- PTFE yarns, silicone rubber core, braided

- Temperature (ºC) 260

- Pressure (Bar) 200

- Velocity (m/s) 22

- PH0-14

- Size: 3×3mm–50×50mm

-

Read more

Chemical, paper, dye and fertilizer industries. Water, steam, oils, solvents, salts, acids and alkalies except for very strong oxidants

- 100% GORE® GFO® fiber

- Temperature (ºC) -240 – 288

- Pressure (Bar) 131

- Velocity (m/s) 21.8

- PH0-14

- Size: 3×3mm–50×50mm